Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

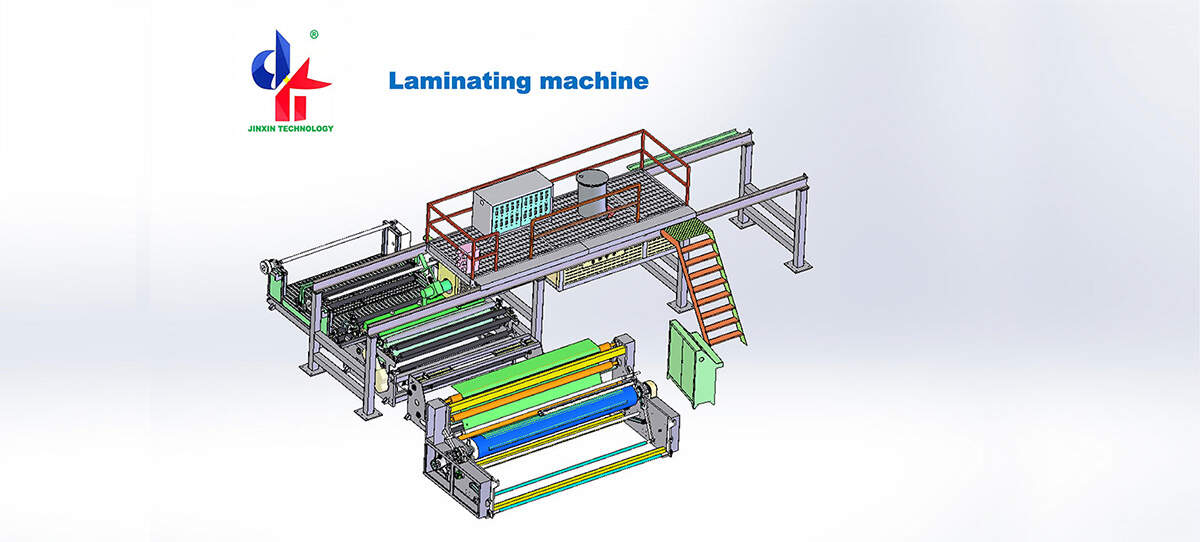

Новая высокоэффективная автоматическая машина для производства нетканых материалов из полипропилена / машина для экструзионного ламинирования

The non-woven fabric bag-making machine can process a variety of non-woven fabric bags with diverse specifications and shapes, including vest bags, purses, leather bags, and so on. Non-woven fabric fruit bags, plastic turnover basket bags, apple bags, and grape bags are just a few of the industrial bags that have recently been added to the market. The machine combines mechanical and electronic components and uses a touch screen for operation.

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

The non-woven fabric bag-making machine applies to non-woven fabric and can process various non-woven fabric bags of different specifications and shapes, such as vest bags, handbags, leather bags, etc. in recent years, the newly added industrial bags include non-woven fabric fruit bags, plastic turnover basket bags, grape bags, apple bags, etc. The machine integrates mechanical and electrical equipment and operates with a touch screen.

Principle of nonwoven bag-making machine

The non-woven fabric bag-making machine sends powder (colloid or liquid) to the hopper above the packaging machine in real-time by the feeder. The introduction speed is controlled by the photoelectric positioning device. The rolled sealing paper (or other packaging materials) is led to the lapel former by the guide roller. After being bent, it is lapped into a cylindrical shape by the vertical sealer. The materials are automatically measured and filled into the bags, The horizontal sealer pulls the bag barrel down intermittently while performing heat sealing and cutting, and finally forms a flat bag with three sides sealed by overlapping longitudinal seams to complete the sealing of a bag.

Characteristics of nonwoven bag-making machine

Ultrasonic welding is used to avoid the use of needles and thread. It saves the trouble of changing needles and threads frequently. There is no broken joint of traditional thread sewing. It can also conduct clean local cutting and sealing of textiles. At the same time, it also plays a decorative role. It has strong adhesive force, can achieve a waterproof effect, clear embossing, more three-dimensional relief effect on the surface, good working speed and product effect, and is more high-grade and beautiful; The quality is guaranteed.

Using ultrasonic and special steel wheel processing, the sealed edge is not cracked, does not damage the cloth edge, and has no burr and curling.

Preheating is not required during manufacturing and continuous operation is possible.

It is easy to operate. It is not much different from the traditional sewing machine. Ordinary sewing workers can operate it.

Low cost, 5 to 6 times faster than traditional machines, and high efficiency.

Processing range of non-woven bag-making machine

The processing range of non-woven fabric bag-making machines is plastic or other material packaging bags with different sizes, thicknesses, and specifications. Generally speaking, plastic packaging bags are the main products. Of course, the non-woven bag-making machine is mainly made of woven fabrics. It not only produces non-woven bag-making machines but also produces various bag-making machines.

Basic technological process of a nonwoven bag-making machine

Feeding (non-woven fabric coil) → folding → ultrasonic bonding → cutting → bag making (punching) → waste recycling → counting → stacking.

This process can be fully automated in time, only 1-2 people are required to operate it, and the production speed and product size can be adjusted within a certain range. It is operated by a touch screen, equipped with a step-by-step fixed length, photoelectric tracking, automatic counting (counting alarm can be set), automatic drilling, and other industrial control devices. To further realize the effect of energy conservation and environmental protection, colleagues have the function of recycling surplus materials in the production process, The automatic collection of the waste materials left in the production process helps to reduce the labor intensity and increase the efficiency of the work.